Copyright © 2021 LS Carbon All rights reserved.Site Map Powered by iwonder.cn

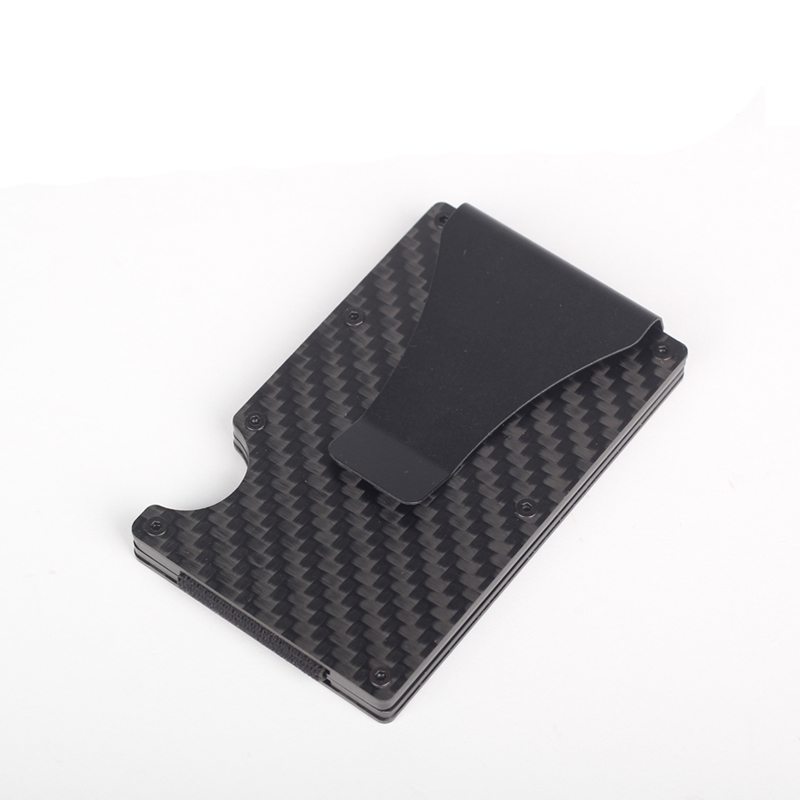

Some friends who have customized carbon fiber products know that the delivery time of carbon fiber products is relatively long. Many people have also asked us why the delivery time of carbon fiber products is long. Now I will explain why the delivery time of carbon fiber products is long with the production process of money clip.

Step 1: Designing carbon fiber moeny clip in order to make 3D model, and making specially processed mold according to the drawing. Before the mold is put into use, more calculation and experiments are needed to sort out the optimal design scheme and processing method. It usually takes a week, and it takes a long time if the product is complex.

Step 2: To make carbon fiber products by pressing, it is necessary to cut carbon fiber prepreg, and customize the shape of the corresponding cutting die.

Step 3: The laying of carbon fiber prepreg is the core of the whole production of carbon fiber products. Among them, the laying of carbon fiber prepreg is the most time-consuming, and the laying of carbon fiber also determines the direction of carbon fiber product lines, and plays a decisive role in the appearance of carbon fiber products.

Step 4 : Molding, first preheat the machine for half an hour, push the laid mold into the molding machine, and use the environment of high temperature and pressure to solidify the prepreg. It usually takes hours.

Step 5: Cooling and demoulding: cool the mould after hot pressing for a period of time for half an hour, and then uncover the mould for demoulding.

Step 6: After the carbon fiber special-shaped parts are formed into blanks, they need to be processed by CNC machine, and the redundant rough edges need to be cut. Some special holes also need to be processed and cut by CNC machine.

Step 7: After forming the carbon fiber products, polishing the surface with sandpaper or grinding equipment to make it smooth and flat. Some joints and positions with radians that cannot be polished need to be polished manually. After grinding, clean the carbon powder particles on the surface and dry them with a dust-free cloth. Put the product in the oven to dry, to ensure that there is no water left.

Step 8: After the carbon fiber products are polished and dried, they can be painted, and they need to be baked once for spraying. Generally, most products need to be sprayed 2-3 times. If there are paint particles or other defects on the surface of products, we need to use a cloth grinder to polish the surface until it is even.

A complete production of carbon fiber products also has the steps of edge cutting, manual grinding, water grinding, etc., which takes a lot of time.

Step 9: There are many customers who need to customize the logo and need to take the silk screen, which usually takes 2-5 days according to the quantity.

Step 10: Carrying out product inspection before leaving the factory. The quality inspection department will compare the qualified samples with the products one by one to eliminate the products with scratched surface, disordered pattern and printing defects.